Types of Industrial Machinery in the Philippines

March 31, 2024

March 31, 2024

What are the common types of industrial machinery in the Philippines?

- Metal steel tanks

- Industrial piping

- Fire protection system

- Wastewater treatment system

- HVAC system

- Conveyor system

- Bottling machine

Overview

- Industrial machinery plays a crucial role in business operations by enabling consistent and efficient production of goods.

- Common machinery types include steel tanks, industrial piping, fire protection systems, wastewater treatment systems, conveyor systems, and bottling machinery.

- Industrial PH excels in creating personalized industrial machinery solutions that cater to the unique needs of your business.

Industrial machinery is the backbone of modern manufacturing, enabling businesses to boost production and maintain consistent, high-quality output. With specialized machines for various tasks, companies can meet diverse needs, access multiple markets, and operate more efficiently.

In this article, we’ll explore the common types of industrial machinery in the Philippines. We’ll highlight some of the tailored machinery solutions offered by Industrial PH to its clientele.

Steel Tanks

Steel tanks play a dual role as storage and processing equipment across multiple industries, including food and beverage, cosmetics, pharmaceuticals, and chemical processing. These vessels ensure the safe storage of water, alcohol, acids, gases, and other substances, maintaining the tank’s integrity and preventing contamination of its contents.

At Industrial PH, we design and fabricate high-quality steel tanks that meet stringent industrial production requirements. Our offerings include customized horizontal and vertical steel tanks, with capacities ranging from 1000L to 250kL, as well as silos. These tanks can store water, juices, oils, chemicals, and other liquids, while withstanding corrosion and extreme temperatures.

Industrial Piping

Industrial piping consists of pipes that transfer liquids, gases, or fine particles. These pipes can be made from aluminum, iron, or concrete, chosen based on the industry’s needs and operating conditions.

They’re crucial in various sectors like water management, manufacturing, engineering, chemicals, and food production for fluid transfer during processes.

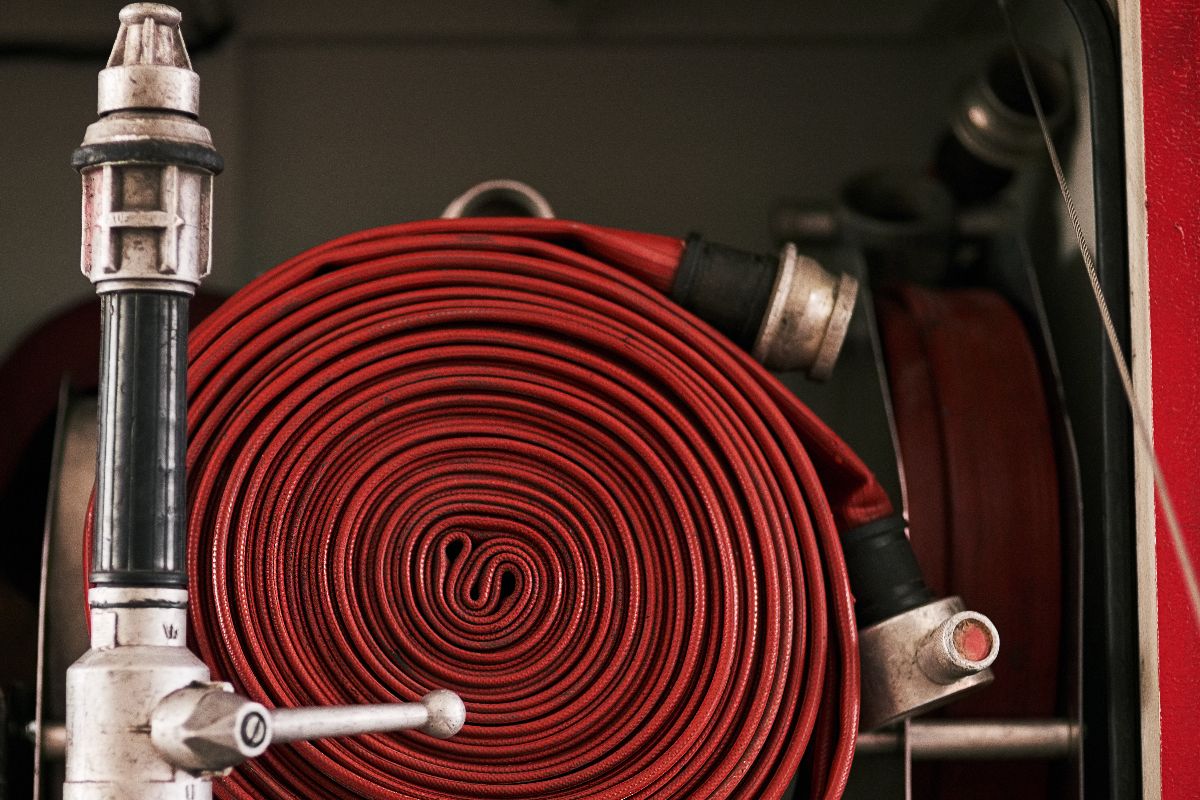

Fire Protection System

State-of-the-art fire protection systems offer significant advantages by minimizing damage to buildings, valuable equipment, crucial documents, and inventory. These systems include a range of tools, including fire suppression systems, smoke detectors, and sprinklers, all of which contribute to early fire detection and the protection of occupants and assets.

Fire protection systems are not one-size-fits-all; rather, they require careful calibration to address the specific needs of diverse industries and settings. Assessing factors such as building layout, occupancy, and specific fire hazards is crucial to ensure the selected system is suitable and meets regulatory requirements.

Wastewater Treatment System

A wastewater treatment system is a complex network of equipment that integrates various processes to effectively manage contaminants and ensure the cleanliness of discharged water. A well-designed system should be versatile enough to handle contamination and flow rate fluctuations, adapting seamlessly to changes.

Using state-of-the-art technology and industry knowledge, our team specializes in designing personalized water treatment systems, including filtration, purification, disinfection, and reverse osmosis, carefully tailored to address your unique water treatment requirements.

Explore Industrial PH’s portfolio of projects to witness our dedication to excellence firsthand.

HVAC System

HVAC systems, as defined by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers, are responsible for taking air, adjusting its temperature, and distributing it into indoor spaces. These spaces encompass individual rooms, entire buildings, or structures such as houses, offices, schools, airports, and even submarines. The primary objectives of these systems include maintaining good indoor air quality through adequate ventilation with filtration and providing thermal comfort.

Different environments and requirements call for various types of systems. When selecting an HVAC system, consider factors such as heating and cooling needs, geographical location, building age, and existing ductwork.

Consulting with a trusted HVAC contractor will help you determine the most suitable system for your specific needs.

Conveyor System

Industrial conveyor systems are designed to efficiently transport materials, with the versatility to be customized according to specific application requirements. These systems are utilized in various industrial settings such as assembly lines, manufacturing plants, construction sites, warehouses, and distribution centers.

Our engineers at Industrial PH design custom conveyor systems tailored to transport materials and products at precise speeds. Our components accommodate heavy loads, meet hygiene standards, and reduce product damage, ensuring suitability for direct food contact.

Bottling Machine

Filling bottles and cans with liquids requires a series of specialized machines dedicated to this task. These machines are designed to precisely dispense a variety of liquids, including food-grade oils, sauces, water, teas, carbonated drinks, and milk, from their respective holding tanks into the bottles. As bottles progress along the assembly line, they undergo inspection, capping, labeling, and subsequent distribution.

Bottling machines are pivotal in the commercial preparation process, facilitating a variety of procedures. Available in different types, some machines are capable of handling multiple tasks, while others focus on specific functions.

Key Takeaway

There are various types of industrial machinery in the Philippines, all capable of optimizing business processes and increasing profitability. Through a comprehensive evaluation of your operations, objectives, and limitations, you can gain a profound understanding of your business requirements. This understanding will enable you to pinpoint the types of machinery that can efficiently assist you in reaching your goals.

Industrial PH assures you of our capability to design and fabricate top-tier industrial machinery in the Philippines that aligns with your rigorous operational requirements. Contact us and inquire today.