How Does a Screw Chiller Work?

August 1, 2024

August 1, 2024

Overview

- This article dives into the mechanics and benefits of screw chillers, showcasing the exceptional features of TopChiller products.

- Discover how screw chillers work, the different types, and why they are the reliable choice for diverse cooling needs.

- As a trusted distributor of TopChiller units, Industrial PH is your gateway to top-tier cooling solutions. We’ll help you select the perfect chiller to enhance your operations and meet your specific requirements.

A screw chiller is integral to maintaining optimal cooling in industrial and commercial environments. Known for its efficiency and durability, this system utilizes advanced screw compressor technology to deliver reliable temperature control.

This article delves into the operational mechanics of a screw chiller, detailing how each component—from compression to heat exchange—works together to ensure effective and efficient cooling. Read on to learn more.

What is the Basic Role of Screw Chillers?

These high-powered circulating chillers remove heat from a specific area and transfer it elsewhere, effectively lowering the environment temperature or process. They manage thermal loads and keep equipment and products at safe temperatures.

This precise control is important in industries like food processing, pharmaceuticals, and manufacturing. In these fields, maintaining exact temperature conditions is essential for product quality and operational safety.

The Refrigeration Cycle in a Screw Chiller

The cooling cycle relies on the smooth operation of its components working together. Understanding each phase’s role helps users optimize their chillers’ performance, ensuring they run efficiently and provide the necessary cooling power.

Suction Phase

The refrigerant enters the screw compressor as a low-pressure gas, drawn from the evaporator where it has absorbed heat from the surrounding environment or process. This phase is crucial for preparing the refrigerant for the next steps in the cooling cycle.

Compression Phase

During the compression phase, the screw compressor increases the pressure and temperature of the refrigerant gas as the two intermeshing rotors turn, compressing the gas significantly. This step is vital as it readies the refrigerant for heat release in the subsequent phase.

Condensation Phase

Next, in the condensation phase, the high-pressure, high-temperature refrigerant gas moves into the condenser, where it releases its absorbed heat to the surrounding environment, typically through water or air. As the refrigerant cools, it condenses into a liquid state, setting the stage for the next part of the cycle.

Expansion Phase

The liquid refrigerant passes through an expansion valve in the expansion phase, causing a rapid drop in pressure and temperature. This cooling prepares the refrigerant to absorb heat again in the evaporator, thus completing the refrigeration cycle and readying the system for another round of cooling.

Heat Absorption

Heat absorption occurs mainly in the evaporator, where the low-pressure liquid refrigerant takes in heat from the environment or process it is cooling. It evaporates as the refrigerant absorbs heat, transforming it back into a gas and becoming ready for the next cycle in the compressor.

Different Types of Screw Chillers Offered by TopChiller

TopChiller, a top manufacturer and supplier of industrial equipment, partners with Industrial PH to provide a range of screw-type chillers tailored to meet the diverse needs of businesses. Here’s a look at their offerings:

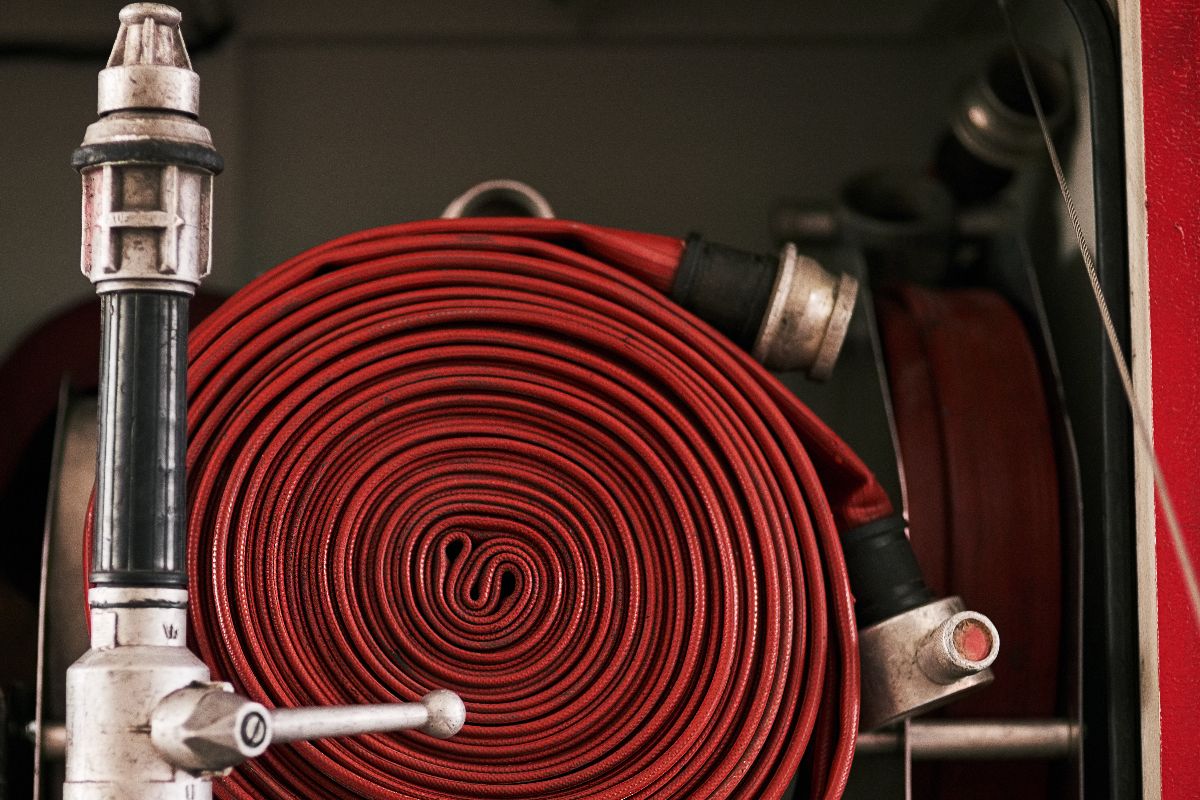

Air-cooled Chiller

Air-cooled screw-type chillers use ambient air to dissipate heat from the refrigerant. These chillers are ideal for locations with limited water resources are limited or where installing a cooling tower is not feasible. Notable features include:

- Cooling Capacity: A range of 50 to 200 tons, catering to diverse industrial requirements.

- Temperature Control: Provide adjustable temperature settings from 5°C to 25°C, allowing for precise management of cooling needs.

- Installation: Eliminate the need for an external cooling tower, simplifying the setup process and reducing installation costs.

- Applications: Industrial processes, hospitals, research facilities, hotels, educational institutions, offices, and any project requiring a continuous and reliable cooling supply.

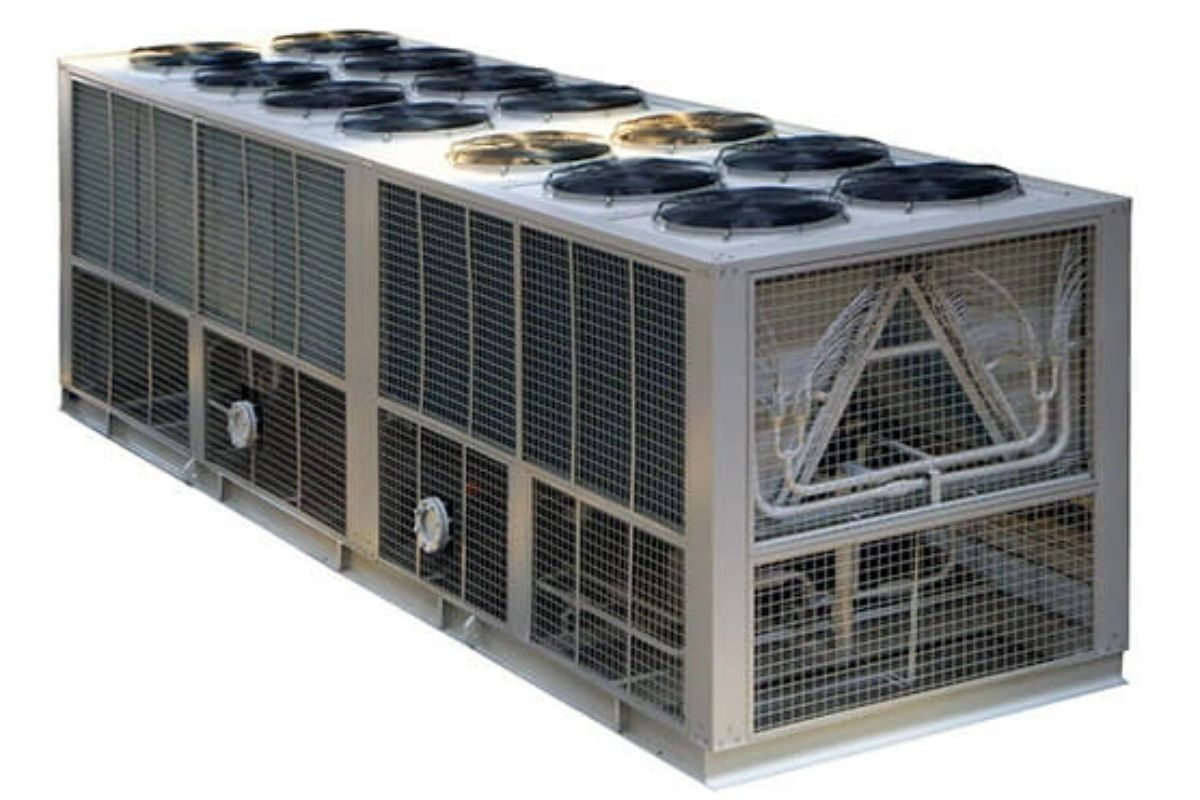

Water-cooled Chiller

Water-cooled units use water to absorb heat from the refrigerant, providing a more efficient cooling solution than air-cooled systems. They are perfect for larger industrial applications with significant cooling needs. Some key features include:

- Cooling Capacity: Available in a wide range, from 50 to 580 tons.

- Temperature Control: Offer a temperature control range from five to 35°C, accommodating various process requirements.

- Water System Integration: Require connection to a circulating water pump and an external cooling tower.

- Applications: Can be utilized in data centers, chemical processing plants, and large manufacturing operations.

Key Takeaway

As technology advances, industrial chiller systems are evolving to meet the increasing demands of industries worldwide. By partnering with a reliable distributor like Industrial PH, businesses can access cutting-edge screw chiller solutions to drive operational excellence and achieve sustainable growth.

As the official distributor of TopChiller products in the Philippines, we deliver reliable cooling solutions designed to fit your needs. Ensure optimal performance and avoid temperature control issues—contact us today for the best in cooling technology.