7 Materials Used for Industrial Ducting

April 14, 2023

April 14, 2023

What materials are used for industrial ducting?

- Galvanized Steel

- Stainless Steel

- Aluminum

- Fiberglass

- Polyvinyl Chloride (PVC)

- Polypropylene (PP)

- Carbon Steel

Industrial ducting is present in many facilities. These pipes play an important role to ensure that many industrial processes run smoothly and efficiently since they are responsible for transporting air and gas that go through the ventilation, exhaust systems, and dust and fume extraction.

In this blog post, we’ll take a closer look at some of the materials used for industrial ducting. Keep reading to learn more!

Galvanized Steel

When a food processing plant needs to transport large volumes of hot air from its ovens to various parts of the facility, the hot air can contain food particles, oils, and other residues that can cause buildup and corrosion in the ducting system.

To overcome this challenge, the plant needs to install a galvanized steel ducting system. Galvanized steel is a highly versatile metal used in constructing many parts of traditional and prefab buildings, and is also a popular material for industrial ducting systems because it is durable, corrosion-resistant, and can handle high temperatures.

The galvanization process involves coating the steel with a layer of zinc, which provides an extra layer of protection against corrosion. This makes galvanized steel ducting an excellent choice for food processing plants.

Stainless Steel

Stainless steel is another popular material used for industrial ducting. Unlike galvanized steel, which is coated with zinc, stainless steel is made from a blend of steel, chromium, and other metals.

In this case, stainless steel would be an excellent choice for a chemical manufacturing plant that produces corrosive gases as part of its production process.

The chromium in the stainless steel provides a protective layer that makes the material highly resistant to corrosion and rust. This means that the ducts would not deteriorate or corrode over time, even when exposed to moisture and chemicals.

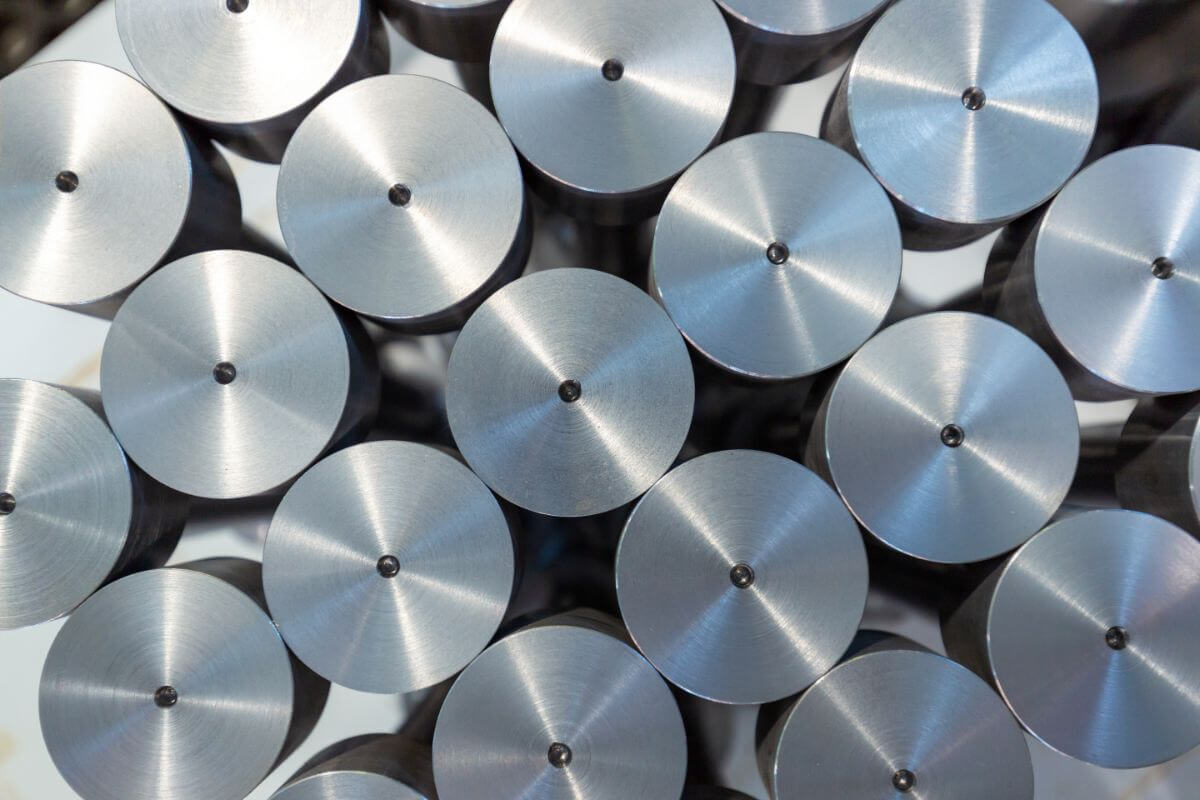

Aluminum

Another common facility that needs industrial ducting is large commercial kitchens. They use this for their ventilation system to remove smoke, heat, and cooking odors from the kitchen area.

Aluminum would be an excellent material choice for the industrial ducting of a commercial kitchen where moisture, heat, and grease are present. This metal is also lightweight and easy to install, making it a cost-effective option for the kitchen’s ventilation system.

However, since aluminum is not as strong as stainless steel, it may not be the best choice for industrial applications that require high levels of durability and strength. In the case of the commercial kitchen, the ducts are not subjected to high pressures or extreme temperatures, so the strength of aluminum is sufficient for the application.

Fiberglass

Fiberglass is another excellent material choice for a ducting system in manufacturing plants. It is highly resistant to corrosion, abrasion, and chemical attack, making it a reliable option for use in environments where chemicals are present just like stainless steel. Additionally, fiberglass is a good insulator, which can help reduce energy costs in HVAC systems.

Polyvinyl Chloride

Another material that is good for an HVAC system is Polyvinyl Chloride (PVC). It is lightweight, easy to install, and resistant to corrosion, moisture, and chemicals. This makes it ideal for use in HVAC applications where these characteristics are important.

PVC is a good insulator, which can help to maintain a consistent temperature within the building and reduce energy costs. This is particularly useful in large office buildings where the HVAC system needs to work efficiently to maintain a comfortable environment for the occupants.

Polypropylene

Another add-on for stainless steel that can withstand chemicals is Polypropylene (PP). This is lightweight, strong, and easy to fabricate, making it an ideal choice for many industrial applications, including chemical transportation.

PP is also able to withstand extreme temperatures, making it a reliable option for use in environments where temperature fluctuations are common. This is particularly important in chemical plants where temperature changes can occur during the chemical production process.

Carbon Steel

Last but not least carbon steel is commonly used in large-scale power plants. Most large-scale power plants generates steam by heating water at high temperatures and pressures. The steam is then transported through a network of ducts to drive turbines and generate electricity.

Carbon steel is a high-strength material that can withstand the extreme temperatures and pressures involved in transporting steam, making it an ideal choice for this application.

However, it is important to note that carbon steel is heavier and more expensive than other materials. In some cases, this additional weight and cost may not be justified. In situations where the extreme strength and durability of carbon steel are not necessary, other materials like aluminum or PVC may be a more cost-effective solution.

Key Takeaway

There are various materials used for industrial ducting available for different industries, each with its unique properties and benefits. The choice of material depends on the specific requirements of the application, such as the level of strength, durability, and resistance to corrosion or other environmental factors. By considering these factors, one can choose the most appropriate material to ensure efficient and effective industrial ducting systems.

With a wide selection of high-quality equipment, from conveyor systems to industrial ducting, Industrial PH has the best industrial machinery that you may need to keep your operations running smoothly. Contact us today to learn more and see how they can help you streamline your industrial processes.